Table of Contents

Current Controller and Peak Lock Servo Board

Model No. ICE-CS1

Document Revision: 1.0

Document Last Updated on 2021/08/26 14:26

Please read Limited Warranty and General Warnings and Cautions prior to operating the ICE-CS1.

Description

The Current Controller & Peak Lock Servo Board has either a 200 mA (ICE-CS1-200) or 500 mA (ICE-CS1-500) precision current source based on the Libbrecht-Hall1) circuit and integrated peak-lock laser servo. The ICE-CS1 contains a tunable PID loop filter for tight locking to the error signal, which is generated by demodulating the internal 4 MHz dither signal on the laser.

Absolute Maximum Ratings

Note: All modules designed to be operated in laboratory environment

| Parameter | Rating |

|---|---|

| Environmental Temperature | >15°C and <30°C |

| Environmental Humidity | <60% |

| Environmental Dew Points | <15°C |

Specifications

| ICE-CS1-200 | ICE-CS1-500 | Units | |

|---|---|---|---|

| Current Source | |||

| Current range | 0-200 | 0-500 | mA |

| Current setpoint resolution | 200 | 500 | μA |

| Current noise density2) | <100 | <200 | pA /√Hz |

| RMS Noise (10Hz - 100kHz)3) | <50 | <100 | nA |

| RMS Noise (10Hz - 1MHz)4) | <100 | <150 | nA |

| RMS Noise (10Hz - 10MHz)5) | <300 | <500 | nA |

| Absolute accuracy | 2 | % | |

| Peak Lock Servo | |||

| Bandwidth6) | 3 | MHz | |

| Input Voltage Range | ±1 | V | |

| Dither Frequency | 4 | MHz | |

| Phase Shift Resolution | 5.6 | deg | |

| Input Voltage Noise7) | TBD | nV/√Hz | |

| Loop Filter Parameters | |||

| Proportional Gain (ref to DC Error) | -22 to +20 | dB | |

| Proportional Gain Resolution | 2 | dB | |

| Integrator | 3, 10, 30, 100, 300 | kHz | |

| Differential | Off, Fixed at 3 times integrator pole | ||

| Differential Gain | 18 | dB | |

I/O (ICE-BOX)

Only when purchased with the ICE-Box.

Laser Current

The Front Panel for the ICE-CS1 has two SMA connectors. The top SMA goes to the laser and drives positive current to the laser. The center conductor of the SMA goes to the laser anode.

Error Input

The Front Panel for the ICE-CS1 has two SMA connectors. The bottom SMA is the Error Input. It is a 50Ω source that measures the laser frequency. Typically this the output of a photodetector looking at saturated absorption spectroscopy (SAS). This input signal must have bandwidth greater than 4 MHz to see the 4 MHz dither on the laser.

I/O (OEM Only)

Only for OEM versions of the ICE-QT1 purchased without the ICE-Box.

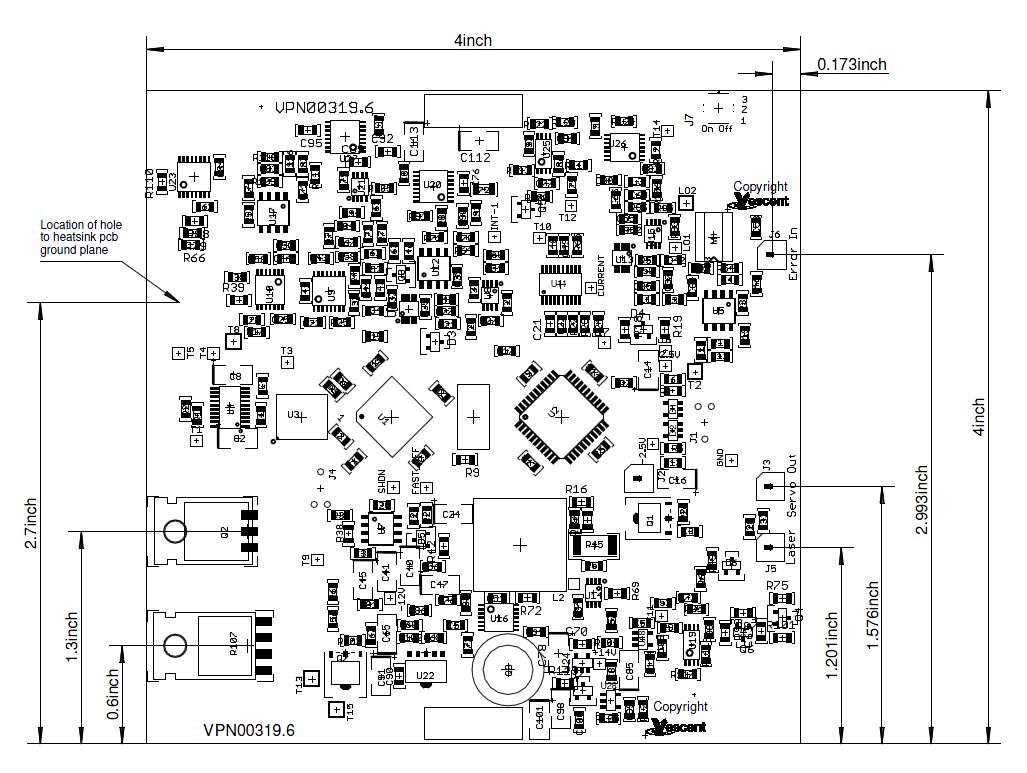

Fig. 1: Component and connector positions on PCB.

Fig. 1: Component and connector positions on PCB.

Laser Current

The ICE-CS1 board has two UMCC connectors. The one labelled “Laser” goes the laser and drives positive current to the laser. The center conductor of the UMCC goes to the laser anode.

Error Input

The ICE-CS1 board has two UMCC connectors. The one labelled “Error In” is the Error Input. It is a 50Ω source that measures the laser frequency. Typically this the output of a photodetector looking at saturated absorption spectroscopy (SAS). This input signal must have bandwidth greater than 4 MHz to see the 4 MHz dither on the laser.

Quick Start Commands Guide (Laser Current)

Please see Overview of Commands and Basic Usage, Common Commands to all Slave Boards and Common Laser Current Controller Commands for a complete command list. Set the ICE-MC1 to communicate with the slot that this ICE-SC1 is in (see Master and Control Board Overview for details).

The ICE-SC1 can drive one laser diode. The first thing to do is set the current limit for your laser diode with the CurrLim command. The command has units of mA.

CurrLim 125 125.0

Next, set the desired current to the laser diode with CurrSet command. The command also uses mA. As usual, the command returns the actual current setpoint which may different from the setpoint send to the ICE-CS1 because of the quantization of the available current setpoints.

CurrSet 110.15 110.2

The status of the laser (On, Off, Fault) can be queried with the Laser? command. And the laser can be turned on or off with the Laser command

Laser? Off Laser On On Laser Off Off

Once the right values are set on the ICE-CS1, use the Save command to save the current settings so that these settings will be remembered when the device is power cycled. Please note that the laser always starts off and must be turned on the the Laser command

Save Success

Quick Start Commands Guide (Peak Lock Servo)

Please see Overview of Commands and Basic Usage, Common Commands to all Slave Boards and Current Controller & Peak Lock Servo Commands for a complete command list. Set the ICE-MC1 to communicate with the slot that this ICE-CS1 is in (see Master and Control Board Overview for details).

This content is not yet available, sorry.