This is an old revision of the document!

Table of Contents

SLICE-QT Four-Channel Temperature Controller Quick Start Guide

Model No. SLICE-QT

Document Revision: 1

Document Last Updated on 2021/08/26 14:26

Please read Limited Warranty and General Warnings and Cautions prior to operating the SLICE-QT.

SLICE-QT Owner's Manual SLICE-QT web page.

Description

The SLICE-QT is a high-precision temperature controller (see figure 1).

Purchase Includes

- SLICE-QT Temperature Control Unit

- AC power cord with appropriate wall plug for you location (if known)

- Four single-ended 6-ft control cables1)

List of Symbols

| Warning. Pay special attention to procedures and notes. |

| Potential for electrical hazard. |

Getting Started

- When presented with a given view, it is possible to select the functionality or change the values in any field bordered in blue. When a particular field is actively being edited, its border will be yellow.

- From the Home screen, touch the CH icon for the channel to be used to go to the Channel Detail screen.

- Touch Settings > Load Limits

- Set the Current and Power limits for you transducer.

- Touch the Return icon.

- Touch Settings > Plant

- Enter in the parameters for your thermistor.

Note: Enter EITHER Beta, Reference Temperature, and Reference Resistance OR the Steinhart-Hart Constants, A, B, and C. The other set of parameters will be automatically calculated. - Select the Transducer Type: either TEC/Bipolar or Heater/Monopolar.

- When choosing TEC/Bipolar, also select Negative of Positive Polarity,

- Using table 1, make connections from the SLICE-QT to your thermal plant via the cables supplied by Vescent. Peel the drain (shield) back to make connections. The shield is grounded at the SLICE-QT. Use caution grounding the shield at the transducer end as ground loops may be formed, degrading performance.

- Use the supplied AC power cord to provide power to the SLICE-QT. The power converter inside the unit will accept any line voltage within the range in table 2.

- Turn on the SLICE-QT with the power switch on the back of the unit located on the power entry module.

- Touch a Channel Label icon to enter the Channel Details screen.

- Touch the Setpoint Temperature Icon to enter in the desired set point temperature.

- Touch Settings > Limits

- Set the absolute minimum and absolute maximum temperature allowed for your plant.

- Set the lock range. This range determines over what value of ∆T = Tact - Tset the system is considered to be locked. If ∆T is outside of this range, the Error field will change from green to yellow. This range will appear as yellow dashed lines on the plot of ∆T vs. time on the Channel Detail screen.

- Touch Settings > PID

- Set the PID parameters for your plant

- Touch each window to set the given parameter

- We recommend the Ziegler-Nichols method of setting your PID parameters2)

- Touch the OFF icon to engage the temperature servo

- Monitor on the performance screen to ensure system settles

| Use caution grounding the shield at the transducer end of the interface cable as ground loops may be formed, degrading performance. |

| WHEN USING A RESISTIVE HEATER, be sure to set the transducer type (CH X > Settings > Plant) to Heater/Monopolar. If set to TEC/Bipolar, attempts by the SLICE-QT to actively cool your plant will result in a thermal runaway condition. |

You may purchase more cables separately from Vescent Photonics. We do not recommend making cables, but if you do so, make sure the metal sleeve (drain) is well.

The SLICE-QT will accept input line voltages within the ranges in table 2.

Front Panel

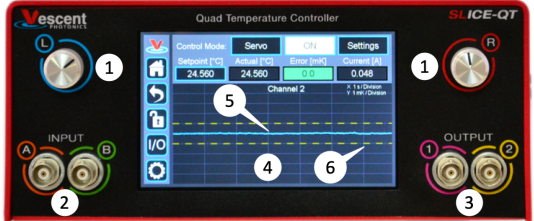

The front panel can be seen in figure 2. The functions and connections are as follows:

- Parameter input adjustment knobs

- Control signal inputs

- Signal monitor outputs

- Touch screen with view of CH 2 Details screen

- ∆T plotted as a function of time (blue line)

- System locked range (yellow dashed lines)

Rear Panel

The rear panel can be seen in figure 3. The functions and connections are as follows:

- Main On/Off power switch

- AC line power in3)

- Output trigger (BNC)

- Input trigger (BNC)

- USB port (Type B)