This is an old revision of the document!

Table of Contents

Quad Temperature Controller Board

Model No. ICE-QT1

Document Revision: 1.0

Document Last Updated on 2021/08/26 14:26

Please read Limited Warranty and General Warnings and Cautions prior to operating the ICE-QT1.

Description

The Quad Temperature Controller Board (ICE-QT1) provides 4 independent PID temperature servo loops capable of sub-mK stability1). Each channel can drive either a single TEC (bipolar current output) or resistive heater (unipolar current output) and read a single 10k thermistor.

Absolute Maximum Ratings

Note: All modules designed to be operated in laboratory environment

| Parameter | Rating |

|---|---|

| Environmental Temperature | >15°C and <30°C |

| Environmental Humidity | <60% |

| Environmental Dew Points | <15°C |

Specifications

| Min | Typical | Max | Units | |

|---|---|---|---|---|

| Temperature Overview | ||||

| Number of channels of Temperature Control | - | 4 | - | |

| Loop Transfer Function2) | - | PID | - | |

| Thermistor Resistance | - | 10 | - | kΩ |

| Temperature Control | ||||

| Temperature setpoint range | -10 | - | 60 | °C |

| Temperature setpoint resolution | 0.1 | °C | ||

| Temperature error resolution | 0.5 | mK | ||

| Max TEC current | 1 | A | ||

| Max TEC voltage | 1 | V | ||

| Electrical Specifications | ||||

|---|---|---|---|---|

| Min | Typical | Max | Units | |

| 5V_A Current Draw3) | 0.5 | 4 | A | |

| 5V_D Current Draw | 60 | mA | ||

| +15V Current Draw | 80 | mA | ||

| -15V Current Draw | 60 | mA | ||

I/O (ICE-BOX)

Applies only when purchased with the ICE Platform.

Laser Temp Output

The Front Panel for the ICE-QT1 has two 8-pin Hirose connector (HR25-7TR-8SA) that each carry the signals for two channels of temperature control. The pin diagram below is for the top Hirose connector; the bottom connect has the same wiring but for channels 3 & 4 instead of 1 & 2. Rth and Rth_Rtn are the two ends of a 10k thermistor.

I/O (OEM Only)

Only for OEM versions of the ICE-QT1 purchased without the ICE Platform.

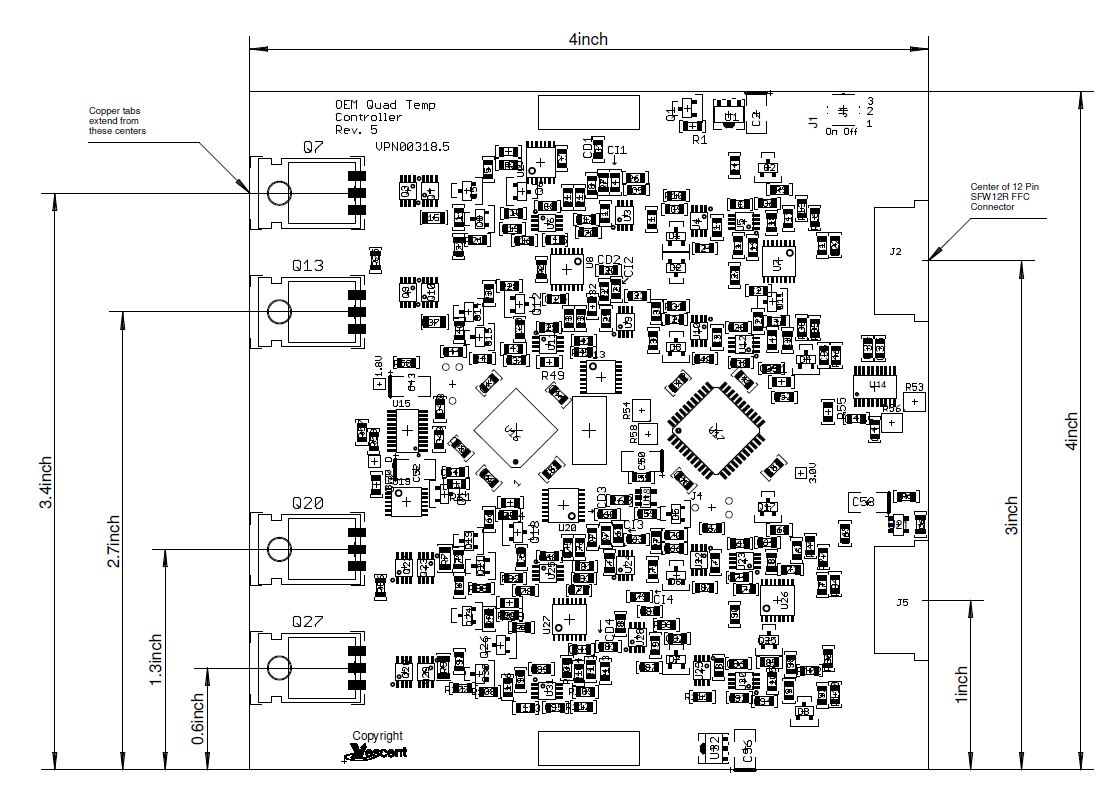

Fig. 1: Component and connector positions on PCB.

Fig. 1: Component and connector positions on PCB.

Temperature Control Output Connections

The ICE-QT1 has two 12-pin 1.00mm pitch flat flex connectors (FCI SFW12R-1STE1LF) shown on the right side of figure 1 that each carry the signals for two channels of temperature control. The left-most connector carries signals for channels 1 & 2 while the right-most connector carries signals for channels 3 & 4. The pin diagram for the top flat flex connector (J2) is shown below and the bottom connector (J5) has the same pin definition for channels 3 & 4. Pin 1 is defined the same as noted in the datasheet for the SFW12R FFC connector and shown below in figure 2. Rth and Rth_Rtn are the two ends of a 10k thermistor. The polarity for the TEC connections uses the assumption that current is flowing from the positive terminal to the negative, the TEC is heating.

Fig. 2: Flat flex connector pin definition (pin 1 highlighted in yellow).

Fig. 2: Flat flex connector pin definition (pin 1 highlighted in yellow).

The flat flex jumper cables used to connect to the FFC connectors should be 1.00mm pitch with 12 conductors. Another FFC connector must be used on the other side to break out the connections for OEM use. It should be noted that when connecting to the other side of the FFC, all the pin definitions will be reversed (i.e. pin 1 on one side will be pin 12 on the other).

Generally with flat flex jumper cables, the cables can be folded but the bend radius should not be less that 2mm. The clearance in front of the pcb FFC connectors must be at least 0.25 inches to allow the flat flex cable to exit and bend. The distance between the FFC connector and the first bend of the flat flex cable is determined by the length of the stiffener (or backing) on the flat flex cable.

Quick Start Commands Guide

Please see Overview of Commands and Basic Usage, Common Commands to all Slave Boards and Quad Temperature Controller Commands for a complete command list. Set the ICE-MC1 to communicate with the slot that this ICE-QT1 is in (see Master and Control Board Overview for details).

The ICE-QT1 has 4 channels of temperature control. Also all commands take the channel number (1-4) as the first argument. To read the temperature setpoint for channel 2, send the command

TempSet? 2 25.0

To change the temperature setpoint, the first agrument is the channel number (1-4) and the second is the desired temperature setpoint. The command will return the actual setpoint, which maybe be different than input setpoint because of the quantization of the available temperature setpoints. For example:

TempSet 2 23.77 23.8

When driving a TEC, the ICE-TM1 should be configured to be in bipolar mode. When driving a resistive heater, turn off bipolar mode. This can be done with the BiPolar command

BiPolar 3 On On BiPolar 4 Off Off

The temperature min and max values can be set with the TempMin and TempMax commands. When the temperature is outside of this range, current to the TEC or resistive heater is turned off. Units are °C

TempMin 3 16 16 TempMax 3 40 40

The temperature servo loop can be turned on or off the the Servo command:

Servo 2 On On Servo 2 Off Off

The temperature can be read with the Temp? command:

Temp? 3 24.56

When the temperature is near the temperature setpoint (within 300mK) the TError? command can read the temperature error (Tsetpoint – Tactual), in units of °C.

TError? 4 0.021

The gain of the temperature loop is set with the Gain command and has a range of 1-255.

Gain 1 56 56

Once the right values are set on the ICE-QT1, use the Save command to save the current settings so that the settings will be remembered when the device is power cycled. Please note that the temperature loop always starts off and must be turned on the the Servo command

Save Success