This is an old revision of the document!

Table of Contents

PCB Mechanical Specifications

This page presents the mechanical specifications for PCB's in the ICE Platform when being integrated by an OEM.

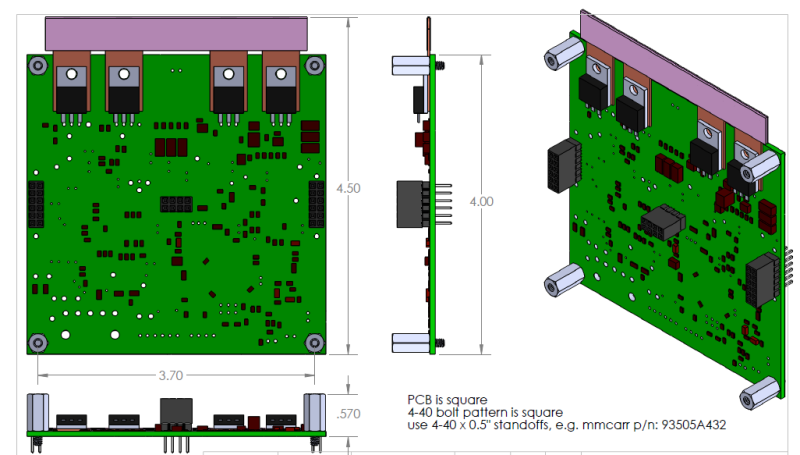

PCB Dimensions

All PCB's in the ICE Platform follow identical board dimensions and header/mounting hole locations. The PCB's themselves are 4 inches square and contain 4 mounting holes for 4-40 screws on each corner. The dimensions of the boards are shown in figure 1. All contain a power bus header on each side (Samtec PN: ESQ-106-13-T-D) and a digital communications bus header (Samtec PN: ESQ-104-13-T-D) in the middle of the PCB. These headers are 0.1 inch pitch board-to-board headers that allow interconnection between boards when stacked, as shown in the next section. At the edge of the board there are copper tabs extending from four IC's (TO-220 package) for heatsinking. Details on proper heatsinking are described in a later section.

Not all circuit boards will utilize all four heatsinking positions and therefore may have copper tabs in only a few positions. The four possible tab positions shown in the drawings will are fixed for every board even though a copper tab may not be utilized there.

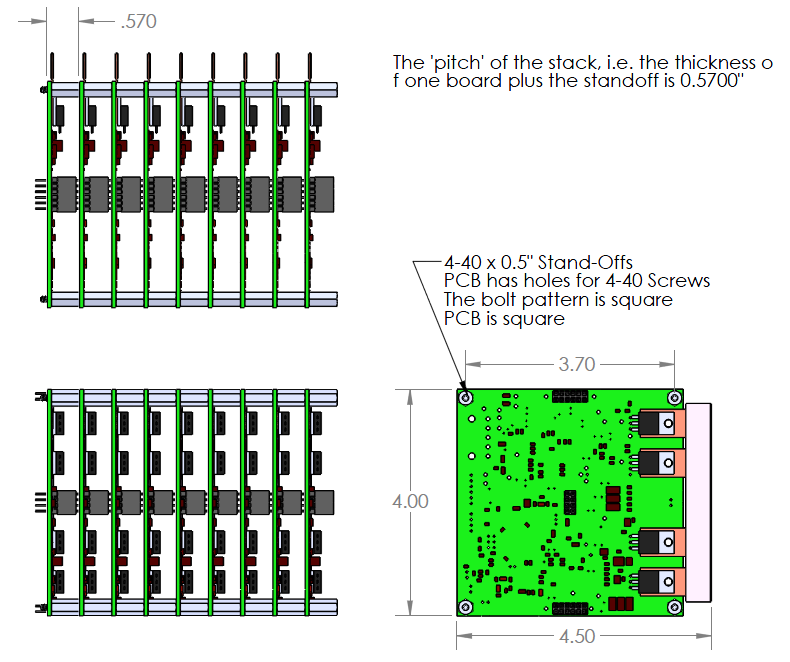

PCB Stackup

The PCB's are designed to stack on one another with each of the board-to-board headers mating, thereby forming a power distribution and communications bus between boards. The PCB's can be stacked by using 0.5 inch length 4-40 standoffs (McMaster-Carr PN: 93505A432) between boards in the four mounting holes at the corner as shown in figure 2. The maximum stack height is 9 boards total.

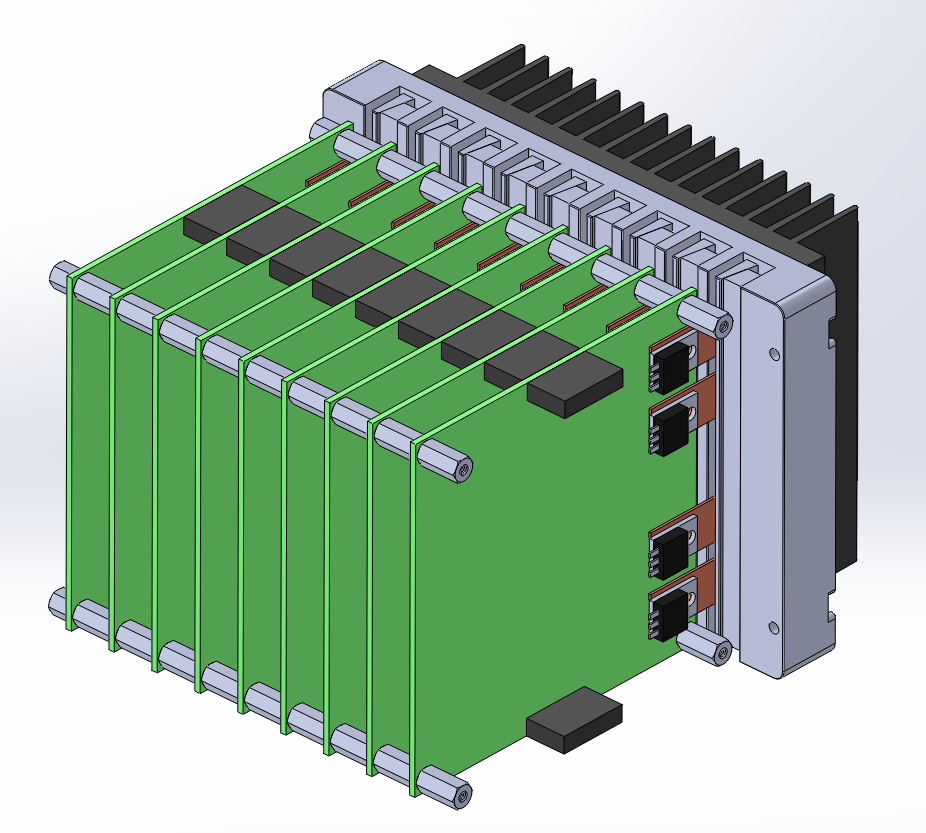

Thermal Management

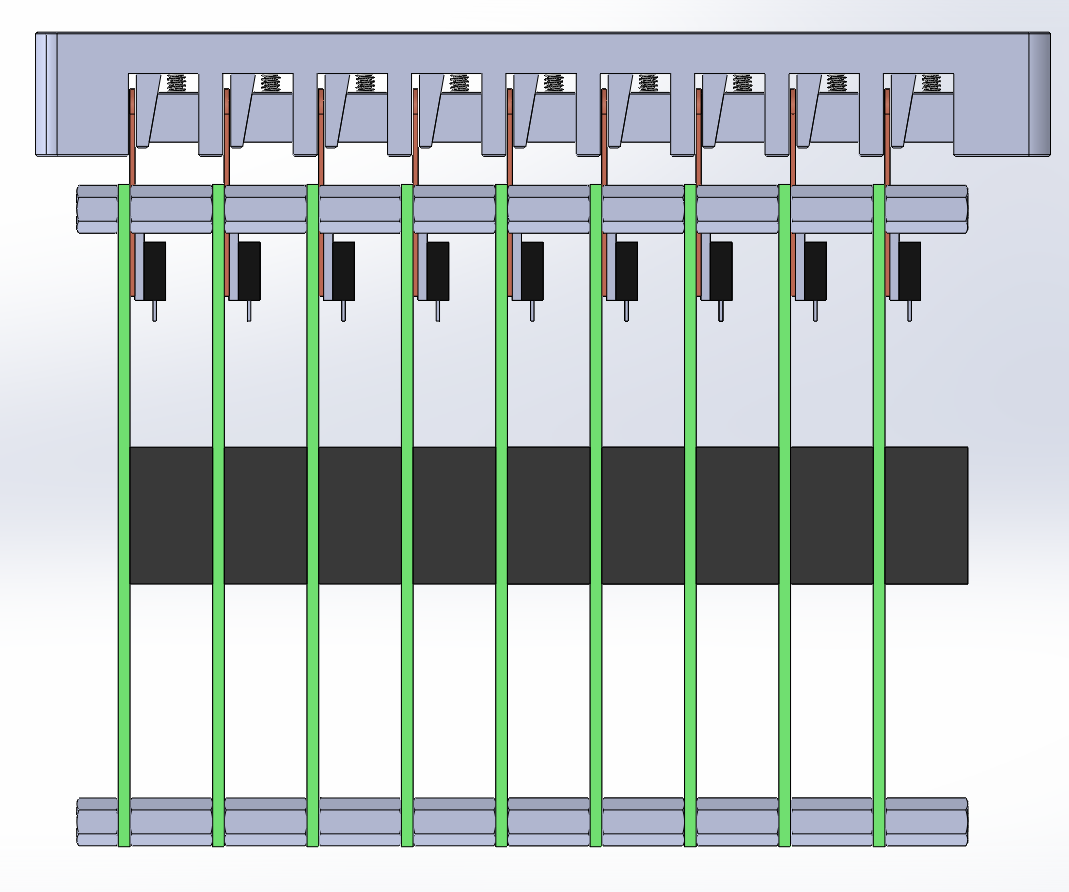

Each PCB exposes up to 4 copper tabs to conduct heat out from power dissipating components to an external heat sink. The copper tabs are not electrically isolated, so electrical isolation is required at the interface between the heatsink and copper tab. Failure to isolate these tabs will result in malfunction of the ICE module. For electrical isolation with good thermal conductivity, Sil-Pad can be used. Sil-Pad requires a certain amount of pressure to ensure good thermal conductivity, so a clamp mechanism should be applied to the copper tabs. In the figure 5, the Sil-Pad is shown in pink. In the ICE Platform enclosure, a wedge-based clamping system is used. The mechanics and dimensions of this are detailed below

The copper tabs must be electrically isolated from the heatsink. For electrical isolation with good thermal conductivity, Sil-Pad can be used.

Fig. 3: Overall pcb heatsink stackup.

Fig. 3: Overall pcb heatsink stackup.

Fig. 4: Top view of the stackup.

Fig. 4: Top view of the stackup.

Fig. 5: Detail view of wedge clamp. Pink material is Sil-Pad for electrical isolation.

Fig. 5: Detail view of wedge clamp. Pink material is Sil-Pad for electrical isolation.