Table of Contents

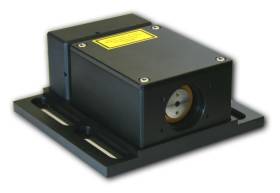

DBR Laser Module

Model No. D2-100-DBR

Document Revision: 2

Document Last Updated on 1970/01/01 00:00

Please read Limited Warranty and General Warnings and Cautions prior to operating the D2-100-DBR.

Description

| The D2-100 laser module is factory aligned. It is not advised that the user attempts to re-align the laser in the field. If the laser becomes misaligned, please return the unit to the factory for realignment. |

The DBR laser module is comprised of a distributed feedback (DBR) laser diode in a precision temperature-controlled housing with beam conditioning optics and an optical isolator. DBR laser diodes are fabricated with the feedback grating patterned directly over the gain section of the diode. They are highly immune to vibrations and by virtue of a very short cavity (~ 1 mm), they can be current tuned over more than 50 GHz. The result is a robust laser capable of very fast servo control for easy locking to atomic transitions. The module contains no moving parts or piezo-electrics and is therefore inherently robust and rugged.

DBR lasers have 2-3 times larger temperature and current tuning coefficients as compared to external-cavity diode lasers. Vescent carefully controls these parameters with two stages of temperature control and a precision low-noise current controller with fast servo input.

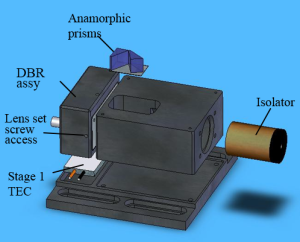

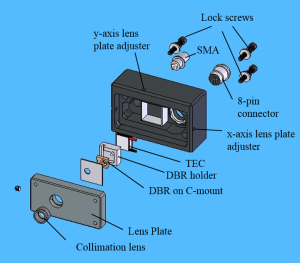

The DBR laser is collimated by a 0.68 NA lens mounted to a movable plate for pointing adjustments. The module also comes with a 35 dB optical isolator and a pair of anamorphic prisms. (Note that prior to fiber coupling we recommend a second stage of isolation.)

The temperature controllers use an 8-pin circular connector on the back of the DBR subassembly (see table 2 for identity of connectors). The injection current connection to the laser diode is through an SMA connector also on the back of the DBR subassembly.

The DBR laser chip is contained in a thermal package allowing temperature control between 15° to 30° C. Vescent can replace the package if it exceeds its lifetime.

Fig. 2: Exploded view of the DBR subassembly

Fig. 2: Exploded view of the DBR subassembly

We use Photodigm Spectroscopy-CertifedTM DBR lasers.

Purchase Includes

- D2-100 DBR Laser

Absolute Maximum Ratings

Note: All modules designed to be operated in a laboratory environment.

| Parameter | Rating |

|---|---|

| Environmental Temperature | >15°C and <30°C |

| Environmental Humidity | <60% |

| Environmental Dew Points | <15°C |

| Stage 2 Temperature of DBR Laser Diode | >15°C and <40°C |

| Laser Diode Current | See datasheet included with your laser. |

The laser should never be operated at a temperature below the dew point temperature for your laboratory conditions. Condensation can form on the laser chip and/or mounting hardware resulting irreparable damage.

Specifications

| Min. | Typical | Max. | Units | |

|---|---|---|---|---|

| Wavelength | 767, 770, 780, 795, 852, 895, 1064, or 10831) | nm | ||

| Output power | 30 | 40 | 50 | mW |

| -HP1 Output power | 100 | Wavelength Dependent | 200 | mW |

| Beam diameter | 0.8 | 1.1 | 1.7 | mm (1/e2 dia.) |

| Polarization | Horizontal | |||

| Optical isolation | 35 | dB | ||

| Operating current | 150 | 180 | mA | |

| Threshold Current | 40 | 50 | 70 | mA |

| Temperature range Stage 1, housing Stage 2, laser | 15 0 | 20 15 | 40 50 (2) | °C |

| Temperature stability | See Laser Controller | |||

| Analog Technologies ATH10KR8 Thermistor | 10k | Ω | ||

| Analog Technologies ATH10KR8 Beta | 3480 | K | ||

| Analog Technologies ATH10KR8 T03) | 25 | °C | ||

| Safety Class | 3B | |||

| Beam height | 0.95 | inches | ||

| Total package Size (L x W x H) | 3.75 x 4 x 2 | inches | ||

Laser Control Signals

Temperature Control Loops

The connections to the TECs and thermistors are made to an 8-pin Hirose connector (see table 2 for identity of connectors). The pin definitions are:

| Connector Location | Connector (Hirose Part Number) |

| D2-105 Bulkhead | HR25-7TR-8SA |

| Cable Connection to D2-105 | HR25-7TP-8P |

| Cable Connection to D2-100 | HR25-7TP-8S |

| D2-100 Bulkhead | HR25-7TR-8PA |

NOTE: Earlier models use a push-pull connector for the 8-pin connector to the DBR module. To remove take care to apply opposition forces with the thumb and forefinger knuckles against the housing. Excessive force could displace the output beam and require realignment.

Laser Current (SMA)

Never connect or disconnect the D2-100 Laser to a laser controller that is energized. Always power down the laser controller completely before making connections to this laser.

Always make sure to make a snug connection between the D2-100 and the current-carrying SMA cable, and between the cable and the laser controller.

Current is provided to the DBR chip through an SMA connector. The central conductor of the SMA connects to the laser anode, and the shield connects to the laser cathode. This is a direct, unprotected connection to the DBR chip, so care must be taken to avoid ESD damage.

Safety Information

The D2-100 is only specified for use with the Vescent D2-105 laser controller, and with cables provided by Vescent.

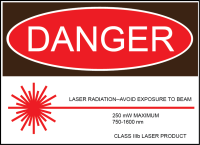

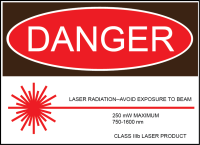

The D2-100 is a Class 3B CW laser product under the guidelines provided in IEC 60825-01:2014. It has no serviceable parts, and should not be disassembled in the field under any circumstance. Viewing of the beam, either directly, with viewing optics, or from a specular reflection can cause damage to the eye, and should be avoided.

The D2-100 is available in many wavelengths, listed above, as well as in a high powered configuration. The maximum specified output of any D2-100 is 200mW under normal operating conditions. However, if provided with too much current, some of the high powered (-HP1) lasers can reach 300mW before experiencing critical optical damage. The beam divergence is < 0.08° in both x and y.

The Maximum Permissable Exposire (MPE) for the D2-100 is 14.45 W*m-2, calculated with a >10s exposure time, and the Nominal Ocular Hazard distance is roughly 100m. Proper eye protection for the D2-100 is highly wavelength dependent. We recommend this online tool, provided by NoIR, and an OD value of at least 3+ for the selected wavelength when choosing the correct eye protection.

There are four safety stickers present on the D2-100. The first, located on the side of the isolator module, is the explanatory sticker, which states the classification of the laser, and several safety instructions. It reads: “Invisible laser radiation avoid exposure to beam class 3B laser product”.

Fig. 3: Reproduction of Explanatory label on the D2-100. \

Fig. 3: Reproduction of Explanatory label on the D2-100. \

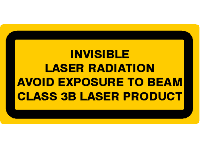

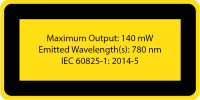

On the side of the isolator module opposite the explanatory sticker is a sticker which lists the maximum possible output of the laser in mW, the wavelength of the laser, and the name of the IEC certification standard to which the laser adheres.

Fig. 4: Reproduction of second Explanatory label on the D2-100.

Fig. 4: Reproduction of second Explanatory label on the D2-100.

On the top of the D2-100, near the laser aperture, is a “Laser Aperture” sticker.

Fig. 5: Reproduction of Laser Aperture sticker on the D2-100.

Fig. 5: Reproduction of Laser Aperture sticker on the D2-100.

Finally, on the sliding beamstop adjacent to the laser aperture, is a triangular laser radiation warning sticker.

Fig. 6: Laser Radiation Warning sticker on the D2-100.

Fig. 6: Laser Radiation Warning sticker on the D2-100.

There is only one laser aperture on the D2-100, located on the front with the isolator as shown in (figure 1).

Safe operation of the D2-100 necessitates that a compliant laser driver be used to supply a current to the diode. It is important to always correctly set the current limit on any laser driver before energizing the laser system. The D2-100 is a Cathode-Ground laser, and requires a DC current between 0mA and 500mA4) to be safely turned on. The connector used to supply current to the D2-100 is a female SMA, which requires a male SMA cable for compatibility.